Questions? Call us!

+1 978-295-7538

Mon-Fri: 9AM - 5PM EST

Containment & Compliance

Explore our professional containment & compliance designed for commercial and industrial applications. Our selection includes models from trusted brands like Abatement Technologies, engineered to deliver reliable performance in demanding environments. With 11+ options available, find the right equipment for your specific facility requirements.

Abatement Technologies AIRE GUARDIAN AG5000 Mobile Containment Dust Cart

Abatement TechnologiesAre dusty job sites affecting productivity? The Abatement AIRE GUARDIAN AG5000 Mobile Containment Dust Cart can help improve air quality. Take Cont...

View full detailsAbatement Technologies AIRE GUARDIAN AG3000MCCC Mobile Containment Cube with Caddy Cart

Abatement TechnologiesEffectively combat contaminants and ensure clean air with the AIRE GUARDIAN AG3000MCCC Mobile Containment Cube, complete with a convenient Caddy Ca...

View full detailsAbatement Technologies AIRE GUARDIAN AG8000 Mobile Dust Containment Cart

Abatement TechnologiesIs construction posing a risk to your facility? Protect it with the Abatement AIRE GUARDIAN AG8000 Mobile Dust Containment Cart. Protect Patients...

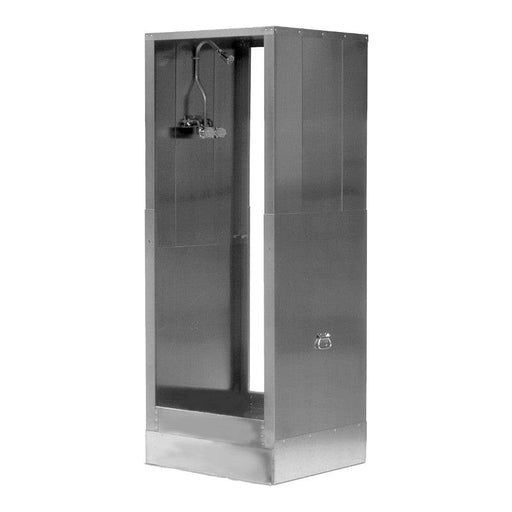

View full detailsAbatement Technologies EASY UP S4000EU Collapsible Decontamination Shower

Abatement TechnologiesSimplify Decontamination Anywhere: Abatement Technologies EASY UP S4000EU Collapsible Shower for Quick Assembly Simplify Your Decontamination Pr...

View full detailsAbatement Technologies S5000ET Teleshower Collapsible Decontamination Shower

Abatement TechnologiesPortable, Efficient, and Durable: The Abatement Technologies S5000ET Teleshower Decontamination Shower Simplify Decontamination with the S5000ET ...

View full detailsContainment & Compliance Equipment for Professional Remediation

Containment & Compliance: Build Proper Containment Barriers

Containment equipment allows you to isolate work areas from occupied spaces during remediation, abatement, and renovation projects where airborne contamination must be controlled. Proper containment barriers prevent mold spores, asbestos fibers, lead dust, and construction debris from migrating to clean areas of the building. Build containment that meets industry standards and regulatory requirements with professional-grade materials and equipment.

Negative Air Equipment

Negative air machines create and maintain pressure differentials that keep contaminated air inside containment while drawing clean air in through controlled entry points. This negative pressure containment is fundamental to proper remediation protocol and is legally required for many hazardous material handling operations. Size negative air equipment based on containment volume and required air changes per hour.

Regulated Work Safety

Containment and compliance products establish the barriers and controls required for asbestos, lead, mold, and other regulated remediation and abatement work. The products include polyethylene sheeting, tapes, warning signs, and personal protective equipment mandated by EPA, OSHA, and state regulations. Containment and compliance products protect workers and building occupants while establishing the documentation needed for regulatory approval. Many contractors maintain comprehensive containment inventories to avoid project delays from missing materials when work begins.

Shop similar collections: Negative Air Machines | Air Scrubbers | Mobile Containment Cubes

Compliance Documentation

Meet regulatory compliance requirements with equipment that includes certifications, test documentation, and specifications needed for regulatory inspections and project documentation. Proper compliance equipment and documentation protects contractors from liability and demonstrates adherence to industry standards for hazardous material handling and contamination control.

Authorized dealers and service centers provide warranty support, genuine replacement parts, and technical expertise for proper equipment maintenance. Factory-trained technicians ensure repairs meet manufacturer specifications for continued reliable performance. Consider total cost of ownership including parts availability and service access when selecting equipment brands.

Let customers speak for us

from 93 reviewsGreat product

This vacuum is very light and powerful

Gets the job done without hassle. This vacuum is powerful and reliable for everyday cleaning. Definitely recommend it.

we have three cats, and this purifier has done wonders in removing pet odors and dander

Located in the Twin Cities in Minnesota, we acquired our Brio Air Filter in mid-late Spring of this year (2023) when pollen count was high and we were beginning to experience the effects of Poor Air Quality Index as a result of smoke particulates from fires in Canada that caused the air in much of Minnesota to become hazy and simply dirty.

It is so easy to share our experience with the Brio Air Filter given how quickly and efficiently it removed pollen, dust, and smoke particles from the environment inside our home. Two people in our home who suffer from pollen-related allergies during the spring immediately experienced easier breathing and elimination of symptoms within the house. With respect to smoke particulates from Canada drifting into our environment, EVERYONE in our home experienced directly improved breathing and smell of the air when entering from outside.

An additional piece of information to account for is that we have always employed high grade furnace filters in our home’s central HVAC system. With that high grade filtration in place both prior to and after acquiring a Brio home air filter, we all quickly agreed that deploying the Brio in our home made an easily noticeable positive difference in breathing inside our home. Additionally, those of us who clean our home have observed that dust builds up slower on our floors and furniture than before we deployed the Brio unit.

We did note that the Brio is not as quiet as a few other brands/models on the market that we have tried in our home but the efficiency and quality of the filtration, along with the air turnover rate it provides,allows us to locate the Brio unit in central rooms away from the bedrooms. Since we made that change there has been no noise-related effect on our sleep, while the unit maintains the same level of air cleanliness throughout our home.

A last key point to make is how easy the Brio unit is to maintain. The simplicity of the modular construction of the Brio unit makes it very quick and easy to keep the filtration sections clean. We have not yet reached a point of filter replacement but it is obvious to us that the replacement will take a matter of seconds and can be executed by anyone in our home, including our 10-year-old son.

this bedroom purifier has transformed my sleep quality. the air is so much fresher and cleaner worth every penny

very customer friendly and professional design.

perfect for maneuvering in tight areas the HEPA filter is a huge bonus

It seems to help reduce my allergy issues. We're glad we bought it. The only problem I had was not seeing any cubic footage recommendations in the online description when purchasing the unit. Bedrooms vary widely in size!!

This vacuum has exceeded my expectations. It's super powerful and handles daily cleaning with ease. I recommend it to everyone.

really effective in sweeping up all kinds of debris from our warehouse floor

works wonders on tough carpet stains. it's compact and easy to use for upholstery cleaning too

this wide area vacuum covers large spaces quickly it’s a huge time saver for our warehouse cleaning

Covers a large area quickly, and the bag is easy to replace. Great for busy offices