Questions? Call us!

+1 978-295-7538

Mon-Fri: 9AM - 5PM EST

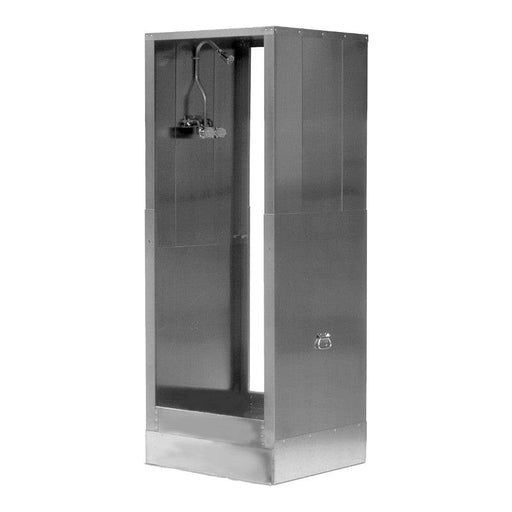

Decontamination Showers - Emergency Decon & Safety Shower Systems

Discover decontamination showers and emergency decon systems engineered for hazmat response, asbestos abatement, and industrial safety. Our portable decon showers, mass decontamination units, and personnel decon systems provide critical safety infrastructure for hazardous material operations, protecting workers and preventing contamination spread.

Professional Decontamination Solutions

Emergency decontamination shower systems remove hazardous materials from personnel before they leave contaminated areas. Required for asbestos abatement, lead remediation, mold remediation, chemical handling, and hazmat response operations meeting OSHA safety standards.

Types of Decontamination Showers:

- Portable Decon Showers - Quick-setup units for temporary job sites and emergency response

- Modular Decon Systems - Multi-chamber units (dirty room, shower, clean room)

- Mass Decontamination Units - Large-capacity systems for multiple simultaneous users

- Emergency Eyewash Stations - Immediate chemical splash response equipment

- Trailer-Mounted Decon - Mobile units for emergency response vehicles

- Personnel Decon Tents - Inflatable structures for rapid field deployment

Decontamination Shower Key Features:

- Multi-Chamber Design - Separation between contaminated and clean areas

- Warm Water Capability - On-demand or tank heating for cold weather operation

- Contaminated Water Collection - Sumps and tanks containing contaminated runoff

- Privacy Enclosures - Full changing areas with ventilation

- ANSI Z358.1 Compliant - Meeting emergency eyewash/shower standards

- Quick Setup - Deploy in 15-30 minutes for emergency response

- Self-Contained Systems - Fresh water supply and waste water storage

- Durable Construction - PVC, polyethylene, or aluminum frames

Applications for Decontamination Showers:

Professional decon showers for sale required in:

- Asbestos Abatement: EPA/OSHA mandated worker decontamination facilities

- Lead Paint Removal: Preventing lead contamination spread to vehicles/homes

- Mold Remediation: Removing spores before leaving containment areas

- Hazmat Response: Emergency decontamination after chemical exposure

- Industrial Chemical Plants: Emergency safety showers for chemical workers

- Hospital Decontamination: Emergency room decon for contaminated patients

- Military & Law Enforcement: CBRN (chemical, biological, radiological, nuclear) decon

- Nuclear Facilities: Radiation decontamination and monitoring

- Pharmaceutical Manufacturing: Personnel decon leaving containment areas

OSHA Decontamination Requirements:

Asbestos Operations (29 CFR 1926.1101):

- Clean room, shower room, and equipment room required

- Workers must shower before leaving worksite

- Contaminated clothing cannot leave in worker vehicles

- Waste water must be filtered before disposal

Lead Abatement (29 CFR 1926.62):

- Shower facilities required when airborne lead exceeds 200 µg/m³

- Change rooms preventing contamination transfer

- Wash facilities for workers eating/drinking on site

Emergency Showers (29 CFR 1910.151):

- Required where corrosive materials or injurious materials present

- Accessible within 10 seconds (approximately 55 feet travel distance)

- Flow rate minimum 20 GPM for 15 minutes continuous

- Tepid water (60-100°F) preventing hypothermia or burns

Decontamination Shower Components:

Three-Chamber Configuration:

- Dirty Room: Remove contaminated clothing, initial cleaning

- Shower Chamber: Full-body decontamination with warm water

- Clean Room: Dry off, dress in clean clothing before exit

Support Systems:

- Water Heating: Propane, electric, or solar water heaters

- Waste Collection: Sumps, tanks, or connection to sanitary sewer

- Ventilation: Negative pressure preventing contamination escape

- Lighting: Adequate illumination for safety operations

- Benches & Hooks: Clothing storage and seating areas

Why Proper Decontamination Matters:

- Worker Protection: Prevent take-home contamination endangering families

- OSHA Compliance: Avoid citations and potential project shutdowns

- Environmental Protection: Contain hazardous materials preventing spread

- Liability Protection: Demonstrate proper safety protocols

- Professional Standard: Industry best practices for responsible contractors

- Emergency Preparedness: Ready response capability for chemical incidents

Selecting the Right Decon Shower:

- User Capacity: Number of workers requiring decontamination daily

- Portability Needs: Frequent moves vs. semi-permanent installation

- Water Source: Municipal connection, water truck, or self-contained tanks

- Heating Requirements: Cold weather operation necessitating warm water

- Waste Management: Filtration, collection, or sewer discharge capability

- Regulatory Requirements: OSHA, EPA, state-specific decon standards

Decontamination Shower Setup:

- Level ground free from contamination for unit placement

- Fresh water supply (garden hose, water truck, or tanks)

- Waste water collection or approved discharge point

- Electrical supply for water heater and lighting (if required)

- Clear pathway from work area to decon facility

- Adequate drainage preventing standing water

Emergency Decon Protocols:

- Chemical Exposure: Immediate 15-minute continuous water flushing

- Remove Clothing: Strip contaminated garments quickly

- Head-to-Toe Washing: Start at top working downward

- Medical Attention: Seek professional care after decontamination

- Containment: Collect all contaminated water and materials

Complete Decontamination Program:

Pair decon showers with: Containment & Barriers, HEPA Vacuum Systems, Negative Air Machines, and PPE & Compliance Kits.

Decontamination Shower Accessories:

- Water heaters (propane or electric) for cold weather

- Waste water filtration systems for discharge compliance

- Privacy curtains and changing benches

- HEPA ventilation units for negative pressure

- Clothing hooks, benches, and storage containers

- Emergency eyewash and drench hose stations

Shop commercial decontamination showers with OSHA compliance consultation, competitive pricing, and fast shipping. Professional personnel decon systems ensuring worker safety, regulatory compliance, and environmental protection for hazardous material operations.